Magnetic Coupled Mixers

for Pharmaceuticals & Biotech

Sterimixer® is the original magnetic coupled mixer designed for biotech and pharmaceutical applications

Original Innovators of

Magnetic Coupled Mixers

Magnetically coupled mixers had existed for years, when more than 30 years ago, Steridose became the first manufacturer to apply and fine-tune the technology for the biopharmaceutical industry. The unique requirements associated with aseptic process design were used to create specialized product ranges such as the Sterimixer and the Sterivalve.

As a leading designer, developer and manufacturer of magnetic mixers, our solutions have been trusted for the most stringent of manufacturing environments for over 40 years.

BENEFITS

Why Choose the Sterimixer® Magnetic Coupled Mixer?

The Sterimixer® provides low and medium shear liquid mixing for process applications that require a high degree of isolation and containment. It can be configured to optimize flow or shear, depending on the application requirements. This results in a higher yield and a more efficient process.

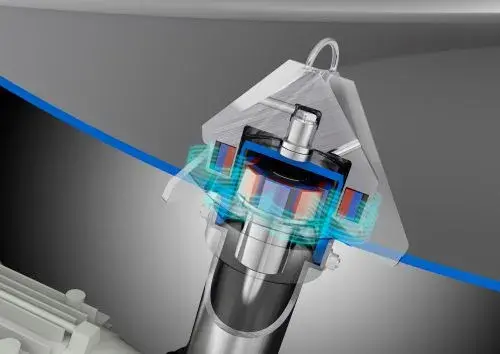

Unlike traditional style mixers, the magnetic coupling on the Sterimixer® enables it to have no physical penetration into the process tank, as opposed to traditional style mixers that require a mechanical seal with a shaft going from outside to the inside of the tank. The absence of a seal eliminates the possibility of seal failure, a common weakness of traditional mixers that reduces containment and therefore sterility. The lack of a seal also reduces the number of components that require cleaning, making this process step more efficient.

The Sterimixer® is designed with the mixer installed on the bottom of the vessel. Low level mixing is a key advantage of a mag mixer, presenting an advantage where space is limited, as there are less fittings on the bottom of vessels compared to the top.

Another key feature of most magnetic mixers is that they utilize a journal bearing whereupon a female bearing inside of the impeller rests or floats on top of a male bearing for stability purposes.

- Containment and isolation: the proven magnetic coupling (no shaft or mechanical seal) means, improved containment. What’s in stays in and what’s out stays out!

- Mixing to the last drop: a bottom mount mixer reduces the minimum mixing volume significantly to increase yields.

- No baffles: the off-center mounting position eliminates the need for baffles, which are always difficult to clean.

- Cleaning: the absence of a shaft or seal allows for easy and reliable cleaning using standard CIP and SIP procedures.

- Compact design: no overhead equipment needed; the mixer is installed safely on the bottom dish.

- Maintenance: safe and easy impeller & drive unit removal.

- Gas entrainment and foaming: this is greatly reduced by offset mixer mounting on the bottom head.

Key Applications of

Magnetic Coupled Mixers

The Sterimixer is perfect for biotech, pharmaceutical, and demanding hygienic and sterile applications such as those involving serums, vaccines, plasma fractions, bacteria and cell cultures, and APIs. Typical applications in this industry include buffer and media prep, blood fractionation systems, Tangential Flow Filtration Systems, Ultrafiltration Skids, storage tanks, heat transfer tanks, powder addition tanks.

It also offers benefits in the food and nutraceutical industries where a high degree of purity and containment is desirable.

Mixer Impeller Options to Optimize Operation

Steridose provides a wide range of impellers for your mixing needs. Whether you require high flow and low shear or high shear forces,

our high-efficiency mixing solutions have you covered.

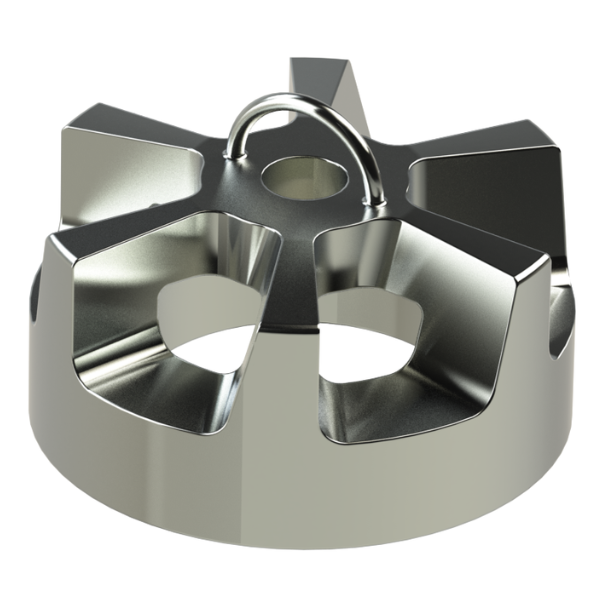

SMA - High Flow and Low Shear Impeller

The SMA is a closed design impeller that is typically used for applications where high flow and low shear are required. It features a patented flow channel. As the impeller rotates, centrifugal force draws fluid into the area surrounding the bearings and flushes it out through the small holes on top of the impeller, providing effective and repeatable cleaning results. It must be submerged during cleaning.

The SMA generates very low shear forces, making it ideal for applications involving shear-sensitive products, such as mammalian cell cultures.

SMO - High Flow and Low Shear Impeller

The SMO is an open design impeller that is typically used for applications where high flow and low shear are required. All surfaces are exposed to a cleaning solution when used with a properly drilled spray ball. It does not have to be submerged during cleaning.

SMMS - Medium Shear Impeller

The SMMS is an open design impeller that provides higher shear forces, which are needed for applications where light or hydrophobic powders must be incorporated. All surfaces are exposed to a cleaning solution when used with a properly drilled spray ball. It does not have to be submerged during cleaning.

Components of a Magnetic Coupled Mixer

Magnetic mixers typically have only four components to them which offers an advantage for maintenance and keeping them operational.

Bearings

Sterimixer bearing assembly consists of a male bearing unit mounted on the weld plate, with a matching female bearing unit mounted in the impeller. Sterimixer products can be equipped with tungsten carbide, silicon carbide or Dri-amond™ (diamond-coated silicon carbide) bearings.

Weld Plate

The weld plate is welded into the tank’s bottom head and is most commonly made from AISI 316L stainless steel. Comparable SMA and SMO models fit on the same weld plate and use the same bearings, making it easy to exchange impeller types. Additionally, most weld plate sizes accommodate more than one diameter impeller, resulting in a very flexible mixer platform.

Radial Design

The magnets that form the coupling are aligned radially, resulting in a magnetic coupling that is strong enough to mix liquids up to 1000 cps.

Drive Units

The drive unit is the driving mechanism for the mixer. It consists of a motor, gearbox, mounting flange, shaft and magnet rotor. Most Sterimixers are equipped with white epoxy coated, washdown duty gearbox and motor. Other configurations such as explosion-proof, stainless steel, and pneumatic are also available. Drive units with an extended shaft are available for jacketed and/or insulated vessels.

Lowering Device

This is an optional feature on Steridose bottom mount magnetic mixers that allows the user to easily break the magnetic coupling without removing the drive unit from the tank. This device is a significant ergonomic enhancement that greatly reduces service time and is particularly useful when working with heavy drive units that can weigh as much as 45 kg (100 lbs).