Magnetic Coupled Mixers for Food & Cosmetic Applications

Sanimixer® — a reliable magnetic mixer for sanitary and sterile processes

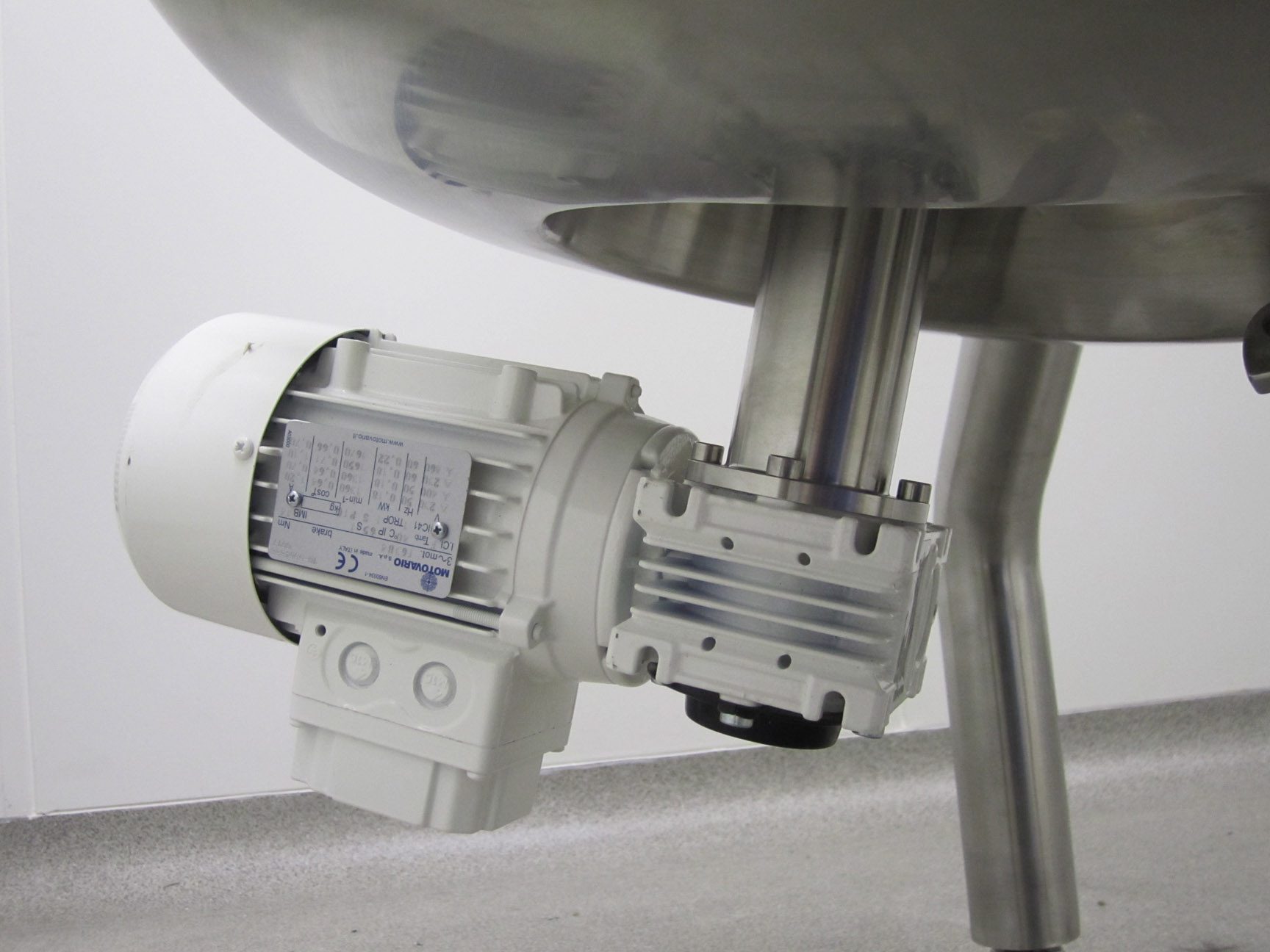

The Sanimixer® magnetic coupled mixer is a cost-effective, high-performance solution designed for demanding sanitary applications in the food, beverage, dairy, cosmetic, and high-purity chemical industries. Built around a proven magnetic coupling with no mechanical seal or rotating shaft through the vessel wall, the Sanimixer® ensures excellent product containment, isolation, and hygiene.

Proven Magnetic Mixing Technology, Optimized for Sanitary Industries

The Sanimixer® is based on the same core magnetic coupling technology used in the Sterimixer® — a premium mixer that has been trusted in pharmaceutical applications for more than 30 years. By leveraging this proven design and adapting it to the requirements of less stringent sanitary industries, the Sanimixer® delivers outstanding performance at a more economical price point.

Available in sizes up to 30,000 L (8,000 US gal) for general mixing and 40,000 L (10,500 US gal) for gentle mixing applications, the Sanimixer® offers the flexibility and scalability needed for modern food and cosmetic processing — without compromising cleanliness, containment, or reliability.

Specifications: